|

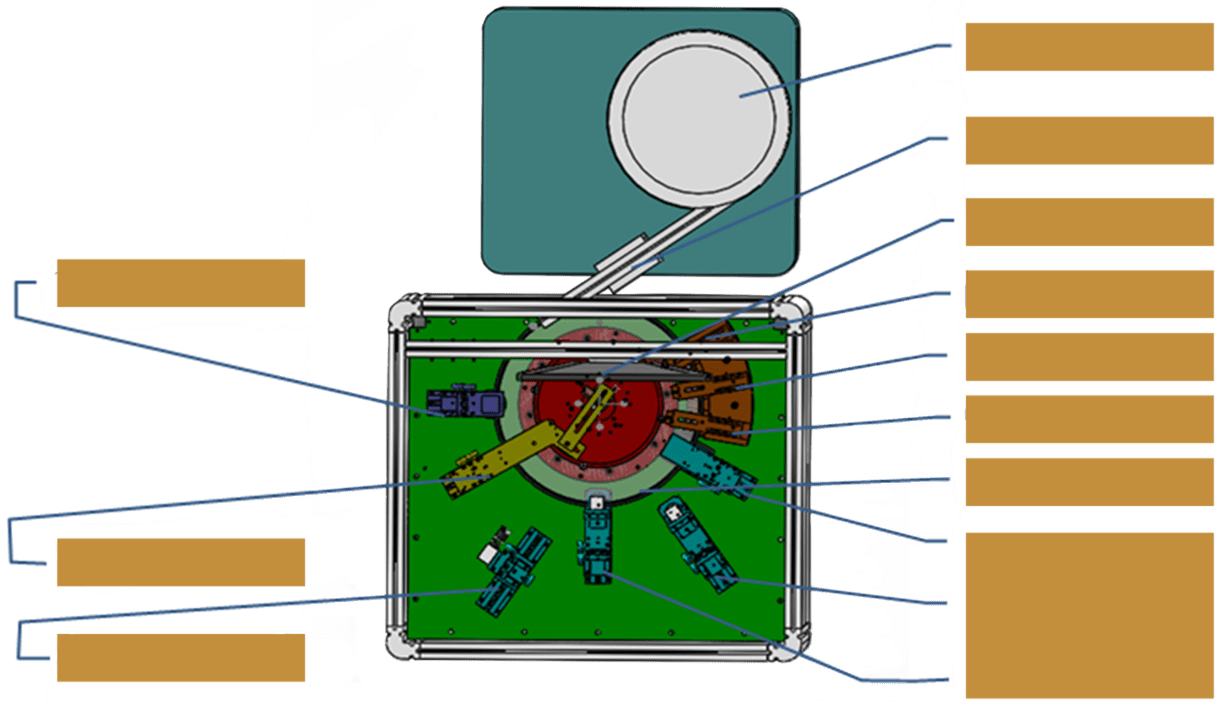

Detection and sort machine

DeepVision blemish detection and sorting machine is widely used in magnetic materials, rubber rings, precision metal parts and other industries and fields.The equipment has the advantages of small size, flexible application, autonomous AI algorithm neural network, simple operation, low maintenance cost, online and offline, etc The big data screen:Real-time update of detection quantity, qualified rate, proportion of defective types and other data information, data viewing is more intuitive。 Appearance material upgrade:New sheet metal baking paint material。 |

|

|

磁材檢測現場圖

|

Collapse, crack, trachoma, concave and convex points, wrinkle, dirt, poor grinding, falling blocks, pores, leakage, bad chamfering, drop corners, pitting, knife grain, holes, inclusions, corrosion, cracking, crystal spots, mucous membrane, slurry, grinding inclination, defect, leakage base material, foreign bodies......(According to different materials and processes, quality inspectors can see defects with naked eyes)

3600-24000 PCS/hour (according to actual demand)

Fatal defects 0 missed detection, total missed detection rate < 0.1%, total misdiagnosis rate < 10%

Sort OK, NG and even abnormal NG, recheck and so on according to actual requirements

Feeding system, according to the product shape preliminary assessment (large customized belt loading and unloading), product loading speed of 60 ~ 400PCS /min (according to the size and shape of the product and other actual conditions)

|

-

New wear,transmitting glass turntable

Efficiency increased by 30%, equipment floor area reduced by half, durability increased by more than 1 times -

New graphics workstation upgrades

The new DeepVision custom graphics processor workstation is easier to use and more powerful to process -

New high speed motion controller

According to the project experience, we will develop a unique operation control system within one year, which can meet the detection efficiency of products of different sizes -

New customized flexible discharging mechanism

Newly upgraded hopper and sound insulation cover, can be compatible with many types of products feeding, the scene environment is quieter.According to customer needs, we can customize hose and belt blanking

-

A new generation of AI algorithm neural network[16 invention patents]

A new generation of AI algorithm neural network[16 invention patents]

Newly upgraded video monitoring failure alarm for key institutions

Newly upgraded video monitoring failure alarm for key institutions

Customizable UI interface and personalization features

Customizable UI interface and personalization features

-

New upgraded optics and hardware architecture

New upgraded optics and hardware architecture

New and upgraded product detection yield curve

New and upgraded product detection yield curve

Can be customized belt, cleaning machine and other loading and unloading mechanism seamless connection production line

Can be customized belt, cleaning machine and other loading and unloading mechanism seamless connection production line

-

New and upgraded device appearance and control interface

New and upgraded device appearance and control interface

Learning cost low production line workers can be maintained

Learning cost low production line workers can be maintained

No threshold production management system docking standard interface

No threshold production management system docking standard interface

Wet magnetic tile

Surface detection

![]() Speed:≥80pcs/min

Speed:≥80pcs/min

![]() Result:Loss ≤ 0.1% | Fault ≤ 15%

Result:Loss ≤ 0.1% | Fault ≤ 15%

![]() Type:Crack, collapse, air hole, bad grinding, bad chamfering......

Type:Crack, collapse, air hole, bad grinding, bad chamfering......

-

master map

-

result

Dry magnetic tile

Surface detection

![]() Speed:≥120pcs/min

Speed:≥120pcs/min

![]() Result:Loss ≤ 0.1% | Fault ≤ 10%

Result:Loss ≤ 0.1% | Fault ≤ 10%

![]() Type:Crack, collapse, trachoma......

Type:Crack, collapse, trachoma......

-

master map

-

result

Ferrite bead

Surface detection

![]() Speed:≥120pcs/min

Speed:≥120pcs/min

![]() Result:Loss ≤ 0.1% | Fault ≤ 10%

Result:Loss ≤ 0.1% | Fault ≤ 10%

![]() Type:Crack, collapse, plug hole, burr......

Type:Crack, collapse, plug hole, burr......

-

master map

-

result

Sintered magnet

Surface detection

![]() Speed:≥100pcs/min

Speed:≥100pcs/min

![]() Result:Loss ≤ 0.1% | Fault ≤ 10%

Result:Loss ≤ 0.1% | Fault ≤ 10%

![]() Type:Crack, corner drop, pitting, knife mark, hole, inclusions, corrosion.....

Type:Crack, corner drop, pitting, knife mark, hole, inclusions, corrosion.....

-

master map

-

result

Soft magnetic core

Surface detection

![]() Speed:≥200pcs/min

Speed:≥200pcs/min

![]() Result:Loss ≤ 0.1% | Fault ≤ 10%

Result:Loss ≤ 0.1% | Fault ≤ 10%

![]() Type:Crack, corner drop, speckle, mucous membrane, slurry, abrasion......

Type:Crack, corner drop, speckle, mucous membrane, slurry, abrasion......

-

master map

-

result

Bonded magnetic ring

Surface detection

![]() Speed:≥100pcs/min

Speed:≥100pcs/min

![]() Result:Loss ≤ 0.05% | Fault ≤ 10%

Result:Loss ≤ 0.05% | Fault ≤ 10%

![]() Type:Cracks, defects, pitting, magnetic flux leakage, pits, foreign bodies......

Type:Cracks, defects, pitting, magnetic flux leakage, pits, foreign bodies......

-

master map

-

result